Top UK Industries That Rely on Permanent Marking Solutions in 2025: Requirements & Key Applications

Permanent marking systems play a vital role across the UK’s industrial landscape. However, different sectors require different marking technologies, materials, and compliance standards. With Datamark’s advanced laser and dot peen marking systems, manufacturers can ensure full traceability, product identification, and long-term durability in even the most demanding environments. As a result, industries ranging from automotive to medical devices rely on permanent marking to meet quality, safety, and regulatory expectations in 2025.

Why Permanent Marking Is Essential for UK Manufacturing

Permanent marking offers several advantages over labels, ink printing, or temporary identification. For example:

- Long-term durability: Marks withstand heat, abrasion, chemicals, and outdoor exposure. This ensures compliance and lifetime identification.

- High precision and readability: Ideal for serial numbers, barcodes, logos, QR and DataMatrix codes used in quality and traceability systems.

- Regulatory compliance: Supports UKCA/CE marking, safety labelling, batch identification, and industry-specific standards.

- No consumables: Permanent marks eliminate the need for inks, paint, or labels. Consequently, operating costs stay low and waste is reduced.

- Compatibility with all materials: Suitable for metals, plastics, coated surfaces, and composite materials.

Key UK Industries Using Permanent Marking Systems

Each industry requires specific marking performance depending on materials, environments, and regulatory needs. Therefore, Datamark offers both laser and dot peen solutions tailored to these applications:

- Automotive & EV Manufacturing: VIN marking, chassis labels, engine parts, and component traceability. In addition, dot peen is widely used for deep, tamper-resistant identification.

- Aerospace & Defence: High-contrast UID codes, serial numbers, and flight-critical component marking. This ensures compliance with strict international traceability standards.

- Oil, Gas & Heavy Industry: Metal tags, valve plates, and equipment labels. As a result, markings stay legible even under extreme conditions.

- Electronics & Electrical Manufacturing: PCB housings, connectors, serialised device panels, and safety labelling. Consequently, laser marking ensures precision without damaging sensitive components.

- Medical Devices & Instrumentation: UDI-compliant markings, stainless steel surgical tools, and plastic device identification. In addition, laser marking guarantees clean, sterile, permanent results.

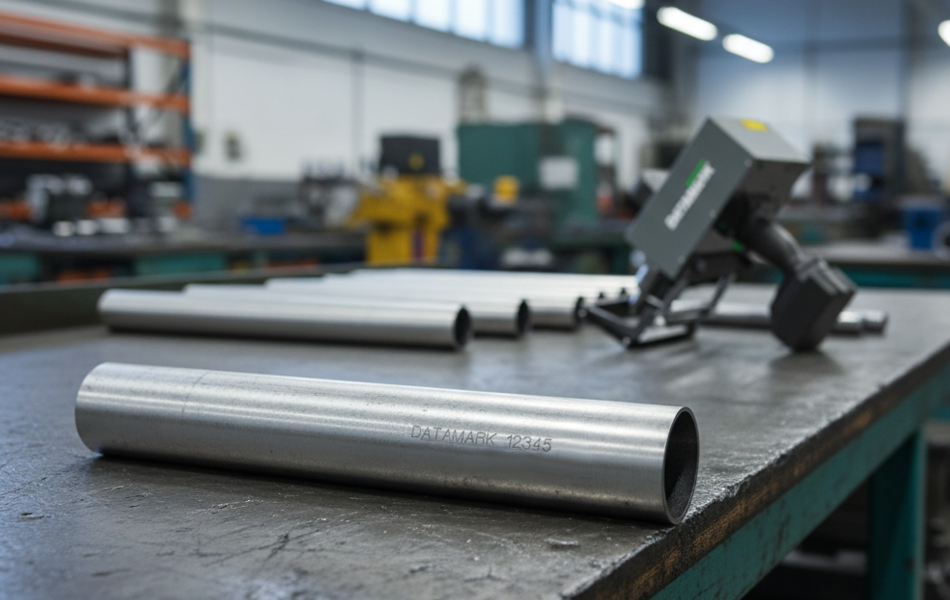

- Metal Fabrication & Workshops: Custom ID plates, small-batch tags, and equipment marking. This provides premium contrast and long-lasting identification.

Industry-Specific Applications for Permanent Marking

Different fields rely on marking for quality control, safety, and product tracking. For instance:

- Automotive: Battery trays, vehicle identifiers, body components, and safety labels. Highly resistant marks support lifetime traceability.

- Aerospace: Turbine components, structural parts, and tooling. Moreover, marks remain stable under extreme temperatures.

- Electronics: Enclosures, micro components, and regulatory symbols. Therefore, manufacturers can maintain full product identification without adhesive labels.

Medical sector: Stainless steel instruments and single-use components. In addition, permanent laser marking meets UDI/Internal NHS requirements.

How Datamark Systems Ensures Reliable Marking in Every Industry

1. Application analysis: First, we evaluate material type, surface finish, and required marking depth or contrast. 2. System configuration: Then, laser or dot peen parameters are tuned for precision, speed, and compliance. 3. Marking execution: Next, identification codes, part numbers, logos, and regulatory marks are applied with industrial-grade accuracy. 4. Quality verification: Finally, each marked component is checked for durability and readability. As a result, every industry receives stable, compliant, and permanent identification.

Why UK Manufacturers Choose Datamark Marking Systems

- Industrial-grade durability: Designed for demanding production environments.

- Versatile technologies: Laser and dot peen systems for metals, plastics, coatings, and composites.

- High-speed performance: Suitable for both manual workstations and automated production lines.

- Reliable traceability: Meets UKCA/CE, aerospace, automotive, and medical standards.

- Low operating costs: Permanent marking without consumables or frequent maintenance.

Conclusion

Permanent marking is essential for UK industries that require reliable identification, safety compliance, and full traceability. With Datamark’s laser and dot peen marking systems, manufacturers across automotive, aerospace, electronics, and medical sectors achieve durable, high-contrast results on all major industrial materials. In addition, Datamark technology ensures consistent performance while reducing operating costs.

Discover Datamark’s marking solutions today and enhance your production with permanent, industry-ready identification.