Part Traceability in Manufacturing: Why Permanent Marking Matters

Reliable part traceability in manufacturing is essential for quality control, regulatory compliance, and customer trust. By marking every component with a unique identifier, manufacturers can track each part from production to end-of-life. In this guide, we explain why traceability matters, how permanent marking technologies like dot peen and laser work, and which Datamark marking systems are best for UK production environments.

Why Part Traceability Is Essential

Implementing part traceability in manufacturing offers a wide range of benefits:

- Quality control: Quickly identify defective batches or materials.

- Regulatory compliance: Meet industry standards in automotive, aerospace, and medical manufacturing.

- Anti-counterfeiting: Protect your brand and products from imitation.

- After-sales support: Enable warranty tracking and recalls.

Permanent Marking Technologies for Traceability

Two main technologies are used to achieve durable, machine-readable markings for part traceability in manufacturing:

Dot Peen Marking

Dot peen, or micro-percussion, uses a stylus to create a series of indents forming characters, numbers, or codes.

- Durable: Resistant to wear, solvents, and heat.

- Cost-effective: Low initial investment and maintenance.

- Great for metals: Ideal for steel, aluminium, and rough surfaces.

Laser Marking

Laser marking uses a focused beam of light to etch or engrave the material surface without contact.

- High precision: Ideal for small codes and logos.

- Fast and clean: No consumables or tool wear.

- Versatile: Works on metals, plastics, ceramics, and more.

Dot Peen vs Laser for Part Traceability

| Feature | Dot Peen Marking | Laser Marking |

|---|---|---|

| Marking Method | Mechanical impact | Laser beam |

| Material Contact | Yes | No |

| Durability | High | High |

| Precision | Medium | Very high |

| Speed | Moderate | Very fast |

| Best For | Metals, rough surfaces | Plastics, anodised metals |

Applications in UK Manufacturing

Permanent marking is used across industries that rely on part traceability in manufacturing:

- Automotive: VIN numbers, batch codes, engine part IDs.

- Aerospace: Serialised components, MRO traceability.

- Medical devices: UDI codes, surgical tool marking.

- General engineering: Nameplates, asset tags, and tools.

For more details on how traceability is applied in regulated sectors, visit this guide on laser marking surgical instruments.

Datamark Marking Solutions

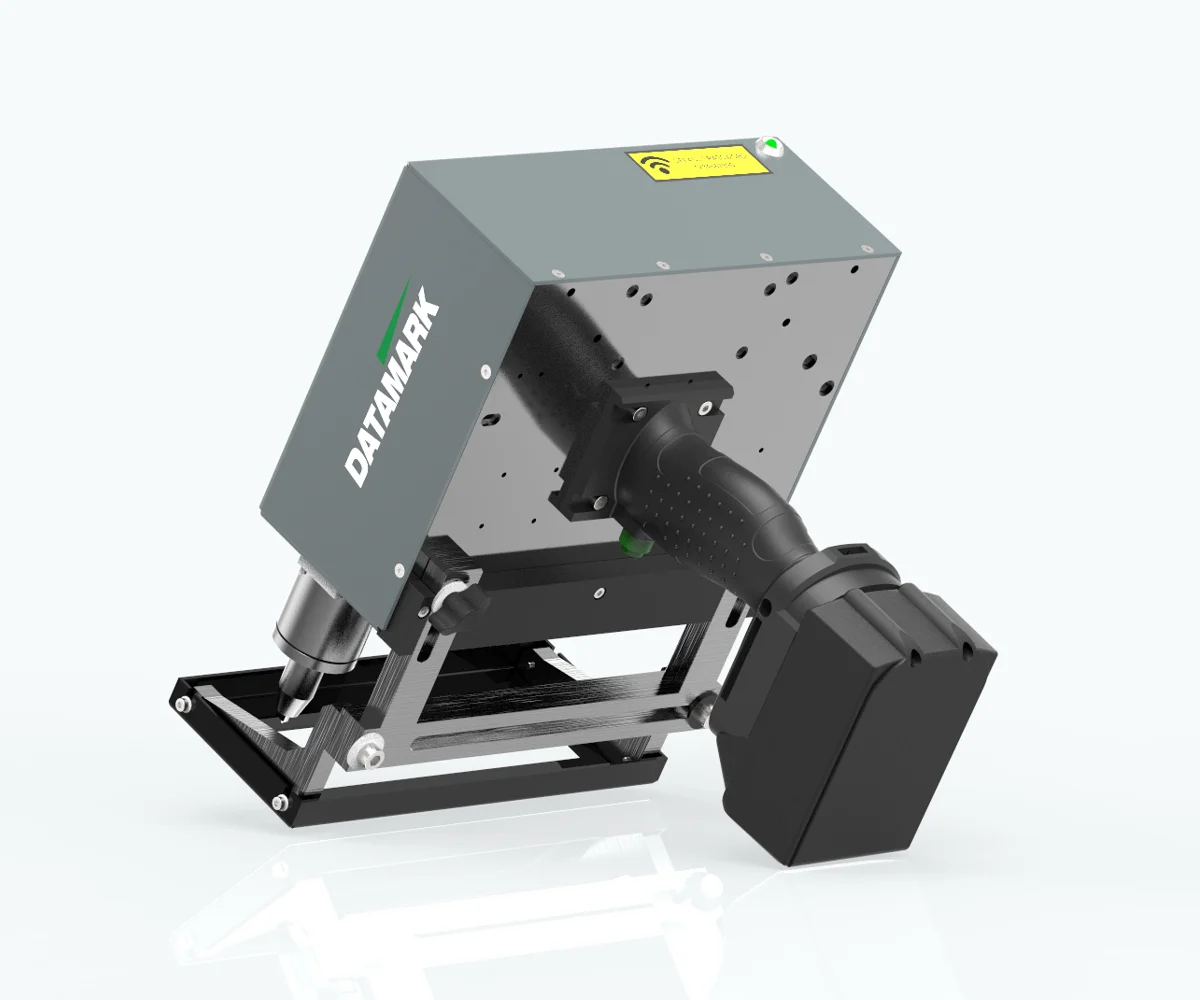

At Datamark UK, we offer robust marking systems to support part traceability in manufacturing:

- Laser marking systems: Fibre, UV, and CO2 laser machines for high-speed, high-precision marking.

- Dot peen marking systems: Portable, benchtop, and integration-ready machines for tough surfaces and heavy-duty environments.

Conclusion

If you need reliable part traceability in manufacturing, permanent marking is the smart choice. Whether you choose dot peen for durability or laser for high precision, Datamark UK has the right solution. Explore our industrial marking systems or contact us for a personalised demo.