How to Choose the Right Nameplate Marking Technology

Nameplate marking is essential for product identification, compliance, and branding. Whether you need to mark aluminium, stainless steel, or plastic nameplates, selecting the right technology ensures durability, legibility, and cost-effectiveness. In this guide, we’ll explore the advantages of dot peen marking and laser marking systems, helping UK businesses choose the ideal solution for their production needs.

Why Nameplate Marking Matters

Nameplates provide critical information about products, such as serial numbers, model codes, manufacturer details, and safety information. High-quality marking ensures:

- Legibility: Easy to read over the product’s lifetime.

- Durability: Resistant to wear, chemicals, and environmental conditions.

- Compliance: Meets UK and international standards for identification.

- Branding: Professional appearance enhances customer trust.

Dot Peen Nameplate Marking

Dot peen marking, also known as micro-percussion, uses a pneumatically or electromagnetically driven stylus to create a series of small dots that form characters, logos, or codes. This method physically deforms the surface, creating a durable mark.

Advantages of Dot Peen Marking for Nameplates:

- High durability: Marks withstand abrasion, heat, and chemicals.

- Cost-effective: Lower initial investment and minimal maintenance.

- Good for rough or textured surfaces: Ideal for metal nameplates with embossed finishes.

Laser Nameplate Marking

Laser marking uses a focused beam of light to alter the surface of the material. Depending on the laser type, it can engrave, etch, or anneal the surface, producing highly precise and permanent marks.

Advantages of Laser Marking for Nameplates:

- High precision: Perfect for fine text, logos, and detailed graphics.

- Non-contact: No tool wear or surface damage.

- Fast marking: Suitable for high-volume production.

- Clean and professional appearance: Excellent for branded products and compliance labels.

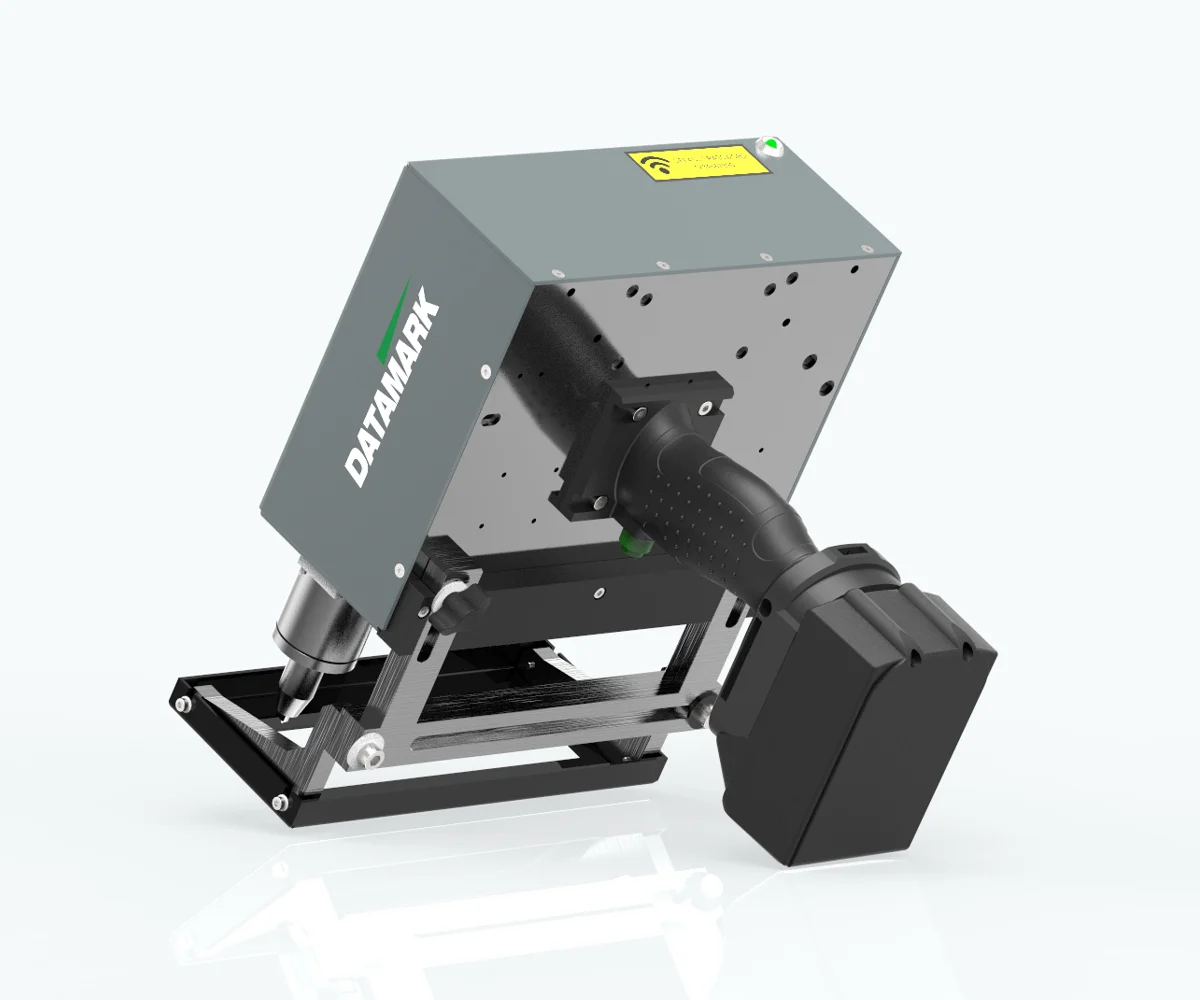

Datamark Nameplate Marking Solutions

At Datamark UK, we offer industrial-grade marking systems for both dot peen and laser technologies:

- Laser Marking Systems: Fibre, UV, and CO2 laser machines available in desktop, enclosed, and integrable versions.

- Dot Peen Marking Systems: Portable, benchtop, and integration-ready machines with air-powered or electromagnetic heads.

Applications of Nameplate Marking

Nameplate marking is used across multiple industries in the UK:

- Industrial machinery: Metal and plastic plates for equipment identification.

- Automotive: VIN plates, model codes, and compliance labels.

- Electronics: Component plates, serial numbers, and logos.

- Medical devices: Durable identification plates for instruments and equipment.

Nameplate Marking Technology Comparison

| Feature | Dot Peen Marking | Laser Marking |

|---|---|---|

| Marking Method | Mechanical impact | Laser beam |

| Material Contact | Yes | No |

| Surface Suitability | Rough, embossed, or coated surfaces | Flat, smooth surfaces preferred |

| Marking Depth | Adjustable (deep marking possible) | Typically shallow (high-resolution engraving possible) |

| Maintenance | Low | Very low |

| Speed | Moderate | High |

| Typical Applications | Industrial nameplates, metal tags, ID plates | Branding, logos, serial numbers, regulatory plates |

| Initial Cost | Lower | Higher |

Conclusion

Choosing the right nameplate marking technology depends on your material, production volume, and durability requirements. Whether you need deep, long-lasting markings with dot peen systems or high-precision, clean results with laser machines, Datamark UK has the solution for your business. Contact us today for expert guidance and a personalised demo.