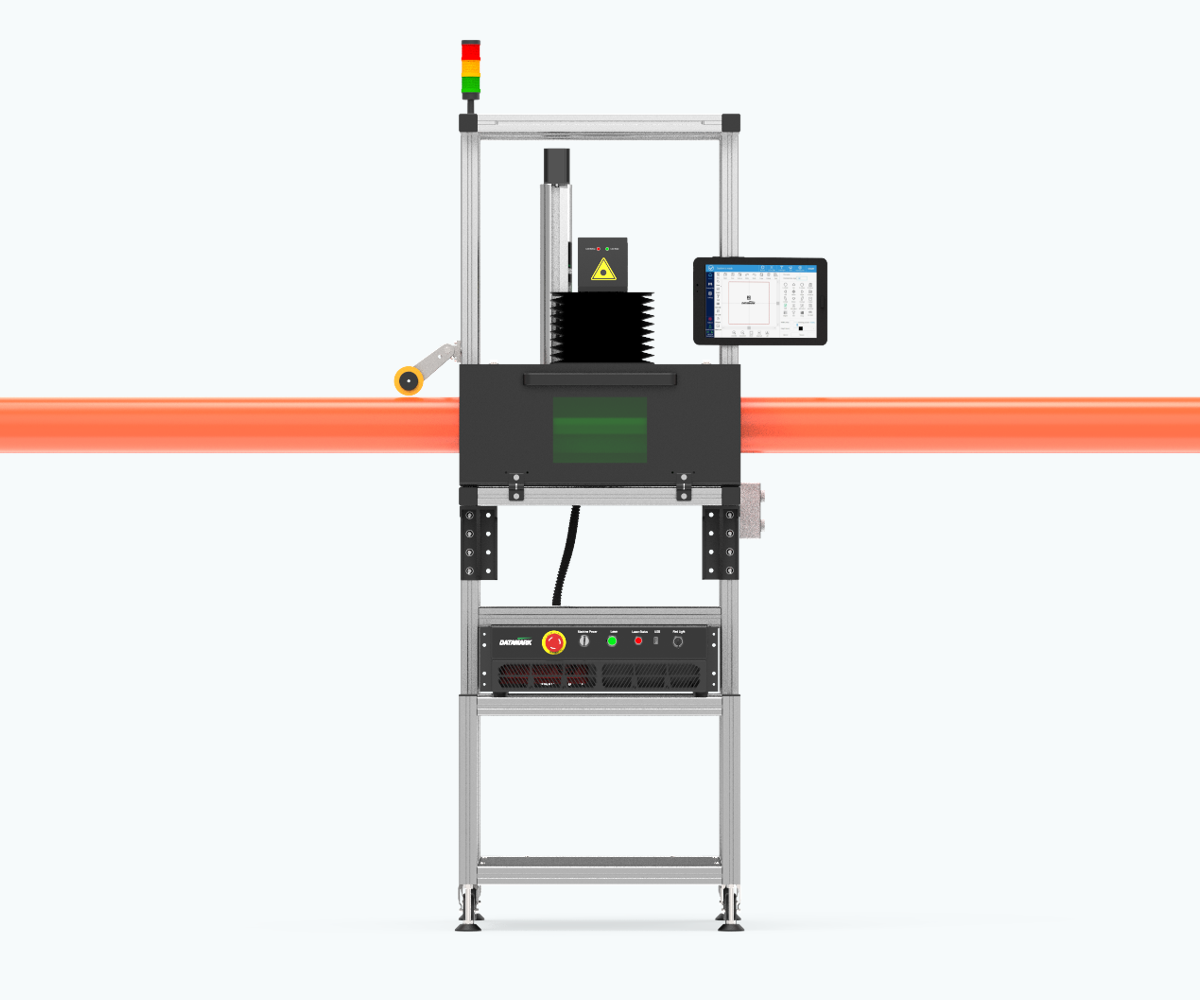

The Datamark Inline Laser Marker for Extrusion Lines is a compact, industrial-grade system developed to deliver clean, high-contrast, and permanent coding directly on fast-moving extruded products—such as plastic pipes, cables, and profiles—during continuous production.

This portable station offers seamless integration into extrusion lines and represents a reliable, cost-effective alternative to traditional inkjet printers. It supports Fiber, UV and CO₂ laser sources to ensure optimal performance on a wide variety of materials including PVC, PE, ABS, silicone, acrylic, polycarbonate, glass, and more.

Key Features

- Laser technology options: Available with Fiber MOPA, UV or CO₂ laser depending on the material to be marked.

- Dynamic marking software: Integrated touchscreen controller with WYSIWYG interface and real-time content editing.

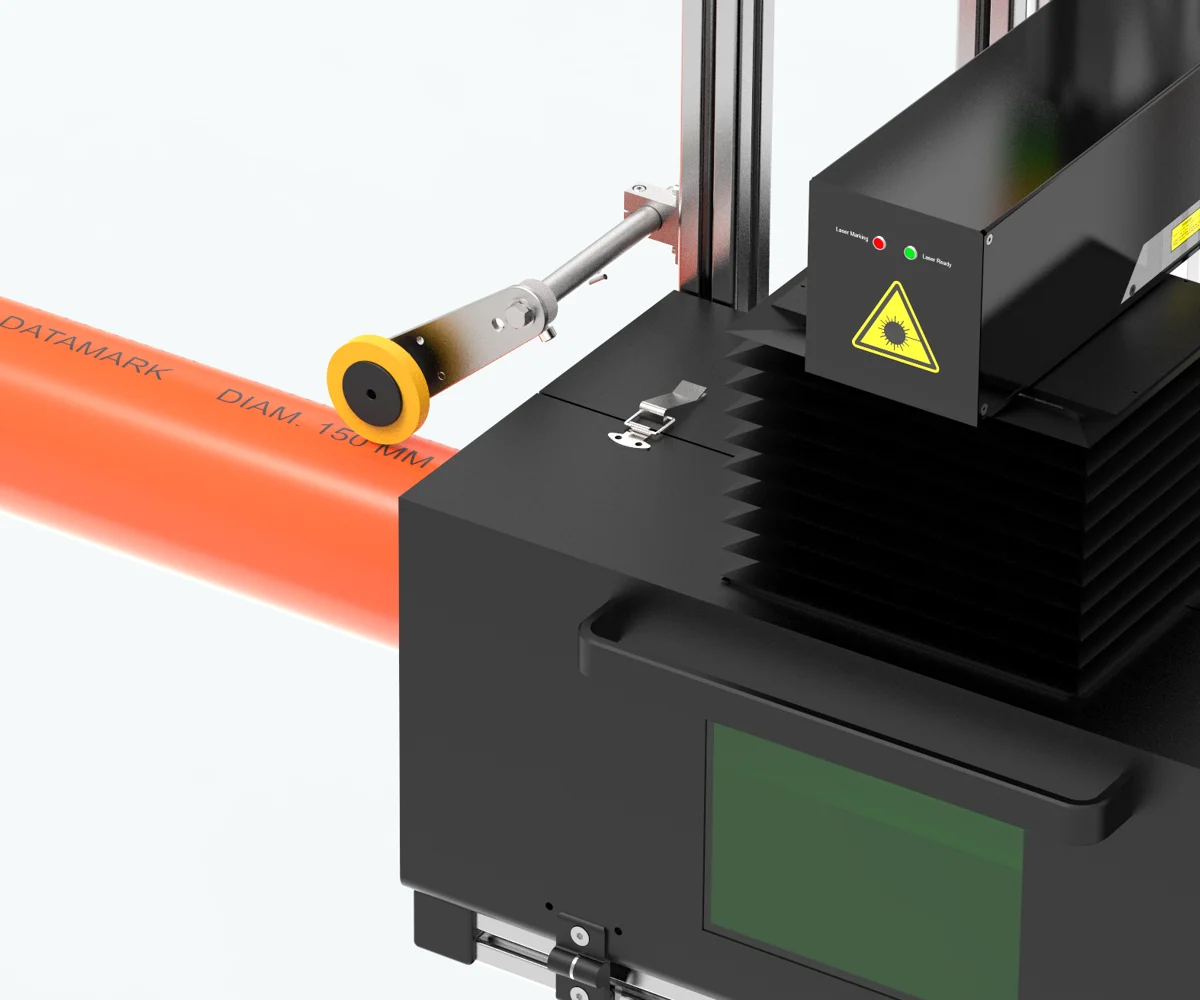

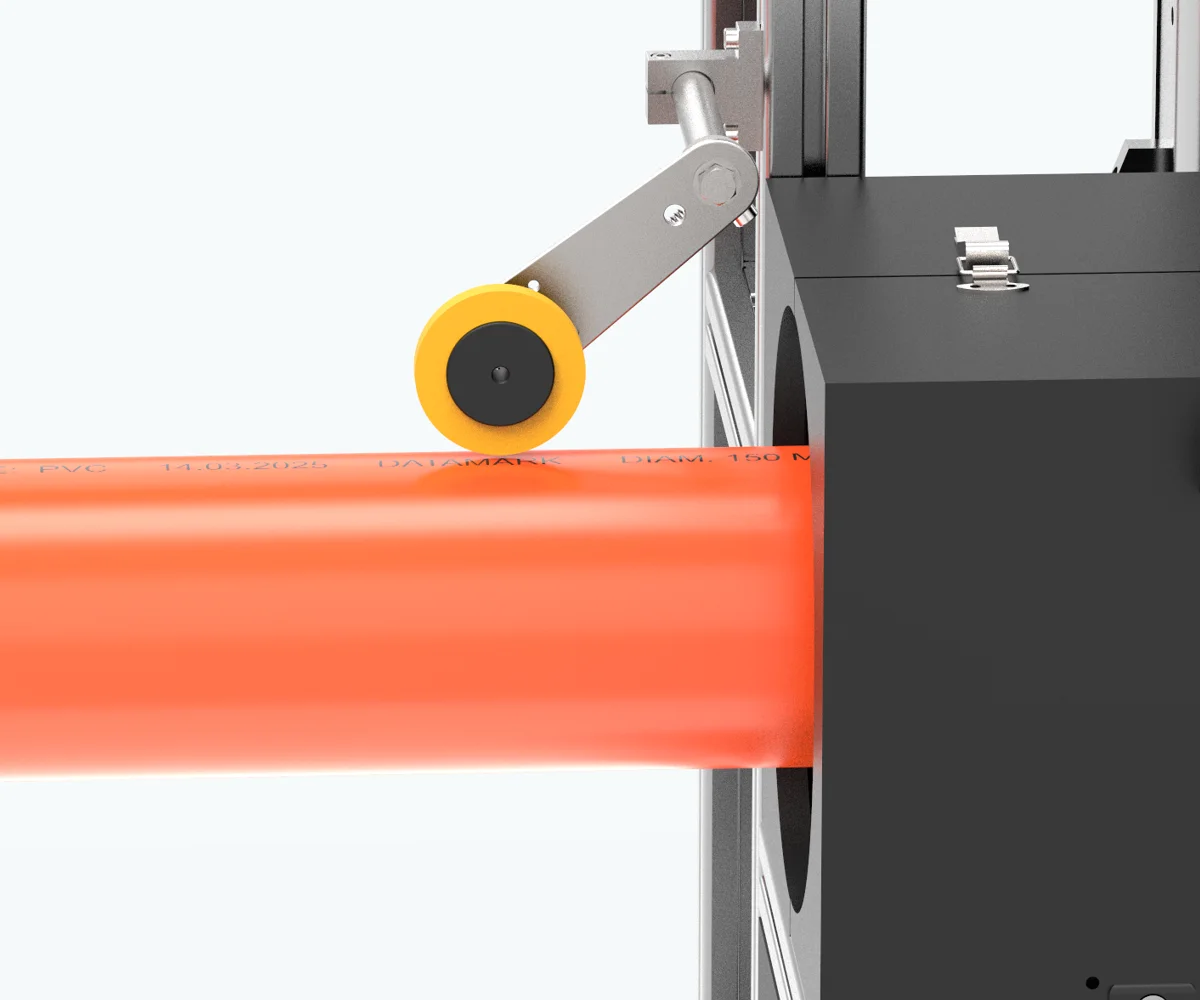

- Encoder-based speed control: Automatically adjusts marking speed to match the extrusion line in real time.

- Flexible mounting: Adjustable height (800–1200 mm) and portable design for easy repositioning between lines.

- Cabin with laser safety Class 1: Operator-safe enclosure with door sensor and optional fume extraction system.

- Automation-ready: Full I/O and TCP/IP connectivity for integration with PLCs and production systems.

- Advanced code support: Linear barcodes, QR codes, DataMatrix, serials, shift codes, logos and more.

- Maintenance-free: Non-contact, consumable-free operation with no moving mechanical parts.

Advantages

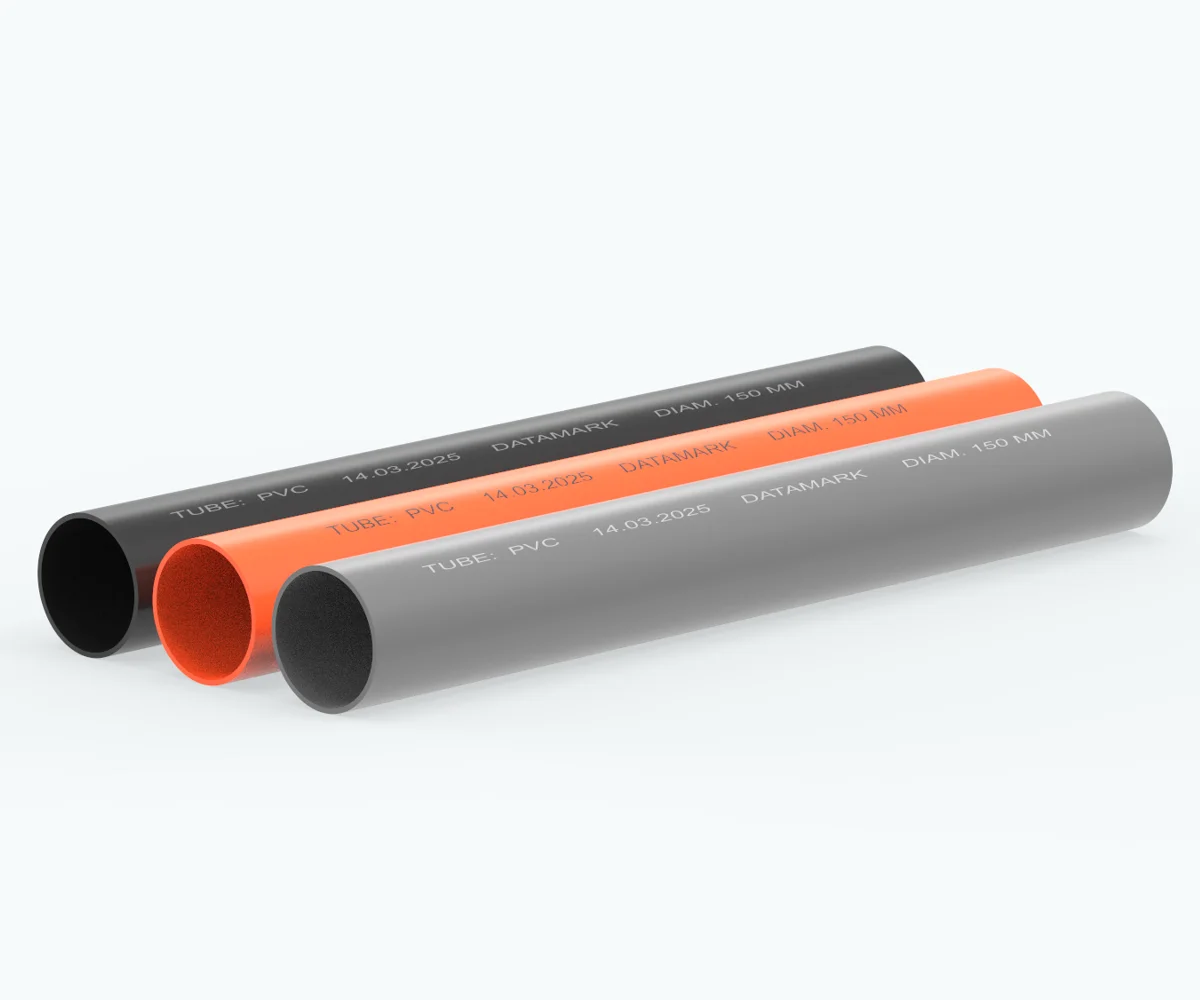

- Clean and permanent markings: High readability codes resistant to abrasion, heat and chemicals.

- Zero consumables: No inks, solvents or printing heads to clean or replace.

- Modular and compact system: Easily adapted to different extrusion lines and production layouts.

- Intuitive operation: Easy-to-use interface with on-screen preview and dynamic layout control.

- Reliable coding process: Prevents typical inkjet issues like smudging, drying, clogging or fading.

Applications

- PVC, HDPE and PEX pipes: Coding of diameters, batches, logos and technical data.

- Plastic and silicone cables: Inline marking of meter counts, identifiers, and production specs.

- Extruded profiles: Marking of window frames, trims, tubes and insulation profiles.

- Transparent or sensitive plastics: UV laser marking on polycarbonate, PET, PMMA, and more.

- Construction and telecom components: Durable traceability and identification on extrusion parts.

Contact Datamark UK

Looking to replace your inkjet printers with a clean, reliable and permanent laser marking solution for your extrusion lines? Datamark UK offers full technical support and free test markings using your real parts to ensure perfect integration and performance.

Contact us today to discuss your application and discover the benefits of laser coding for extrusion.

| Marking Technology | Laser |

|---|---|

| Machine Type | Integration |

| Laser Safety | Class 1 |

| Laser Source Type | CO2, MOPA Fibre, UV |

| Laser Power | 100W, 30W, 50W |

| Marking Window | 110×110 mm |

| Connectivity | Digital I/O, Ethernet TCP/IP, USB |

| Sofware | Touchscreen |