FAQs

Find answers to common questions about Datamark dot peen marking systems. Discover how this robust and reliable technology allows you to mark all types of parts — from large industrial components to small ID plates — with precision, durability and total flexibility, both in the workshop and on the field.

Dot peen marking is a mechanical process where a hard stylus (usually carbide or tungsten) strikes the surface of a part to create a series of permanent dots. These dots form characters, logos or codes, and are ideal for industrial identification.

Instantly provides permanent, deep and long-lasting marks — even on rough or coated surfaces. Dot peen is cost-effective, works without consumables, and is ideal for metal parts used in demanding industrial environments.

Dot peen marking is ideal for marking metals and other hard surfaces, including:

- Steel (carbon, stainless)

- Aluminium and alloys

- Brass, copper

- Cast iron

- Coated, galvanised or painted surfaces

- Some plastics and hard polymers

Dot peen marking is an extremely versatile technology, suitable for marking virtually any industrial part, regardless of size, shape or material. With Datamark systems, you can mark:

- Large or heavy parts, such as structural profiles, frames, pipes, tanks, engine blocks or castings — especially using our portable models.

- Flat, cylindrical or irregular surfaces, even those with coatings, galvanisation or surface treatments.

- Small and medium-sized components, including gears, fittings, machined parts, tools, valves and metal enclosures.

- Curved surfaces, such as tubes, shafts or rings, with consistent marking depth and alignment.

- Metal nameplates and identification tags, easily marked using our benchtop machines or by mounting portable models on the optional support column.

From individual parts to batch production, Datamark dot peen systems offer the flexibility to mark anything from a tiny nameplate to a steel beam — with permanent, high-quality results.

Our machines can mark text, serial numbers, batch and shift codes, logos, and 2D datamatrix codes. All marks are permanent and traceable.

Yes. Dot peen creates deep, physical marks that resist wear, vibration, painting, galvanizing, shot blasting and harsh industrial conditions.

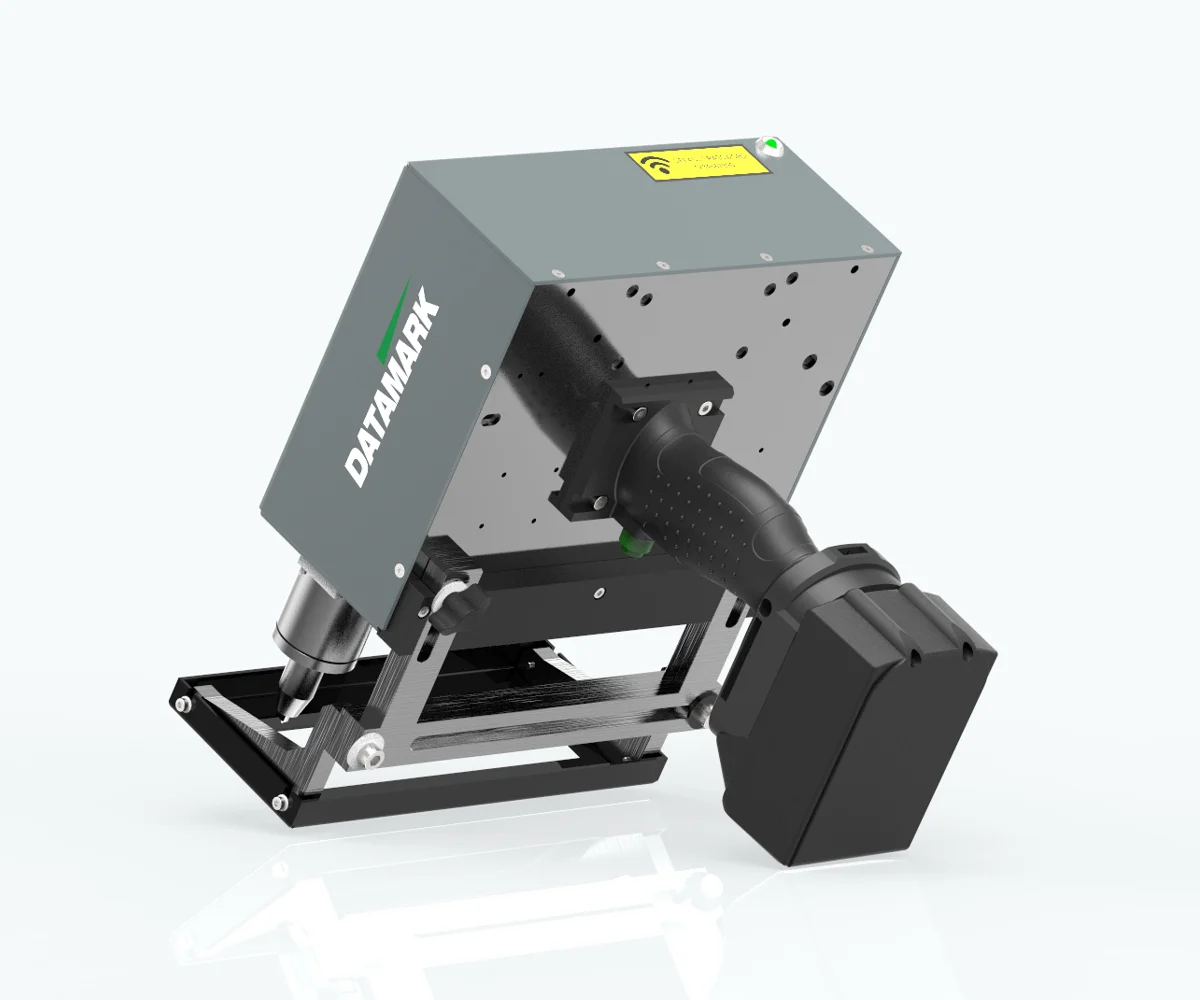

Yes. Datamark offers a full range of battery-powered, fully portable marking systems that are ideal for marking large, heavy or fixed parts on-site. They are lightweight, robust and easy to use without any cables.

Yes. Datamark systems can mark metals up to 62 HRC and can handle slightly curved or uneven surfaces with consistent marking quality.

Marking depth depends on material hardness and machine model, but Datamark systems can produce deeper marks suitable for post-processing like painting, galvanizing or shot blasting.

Yes. Datamark dot peen machines can mark high-contrast, readable 2D datamatrix codes that comply with traceability standards.

Datamark machines provide high positional accuracy and adjustable force, allowing precise control of character size, spacing and depth.

Yes. Our integrable machines offer I/O and serial communication for seamless integration into automated manufacturing and assembly lines.

Maintenance is minimal. The stylus may need occasional replacement depending on use and material hardness. The systems are built for long life in industrial settings.

Yes. They are designed with a robust metal casing, industrial-grade components and are tested to perform reliably in harsh environments.

We offer pre-sales advice, live marking tests, delivery, setup and operator training, along with technical support and fast spare parts from our UK team.