What’s the Difference Between Dot Peen and Laser Marking?

Both dot peen marking and laser marking are widely used for industrial part identification; however, each technology serves different needs. In this guide, we will explore the advantages of both and explain which Datamark marking system is best suited for your production process.

How Dot Peen Marking Works

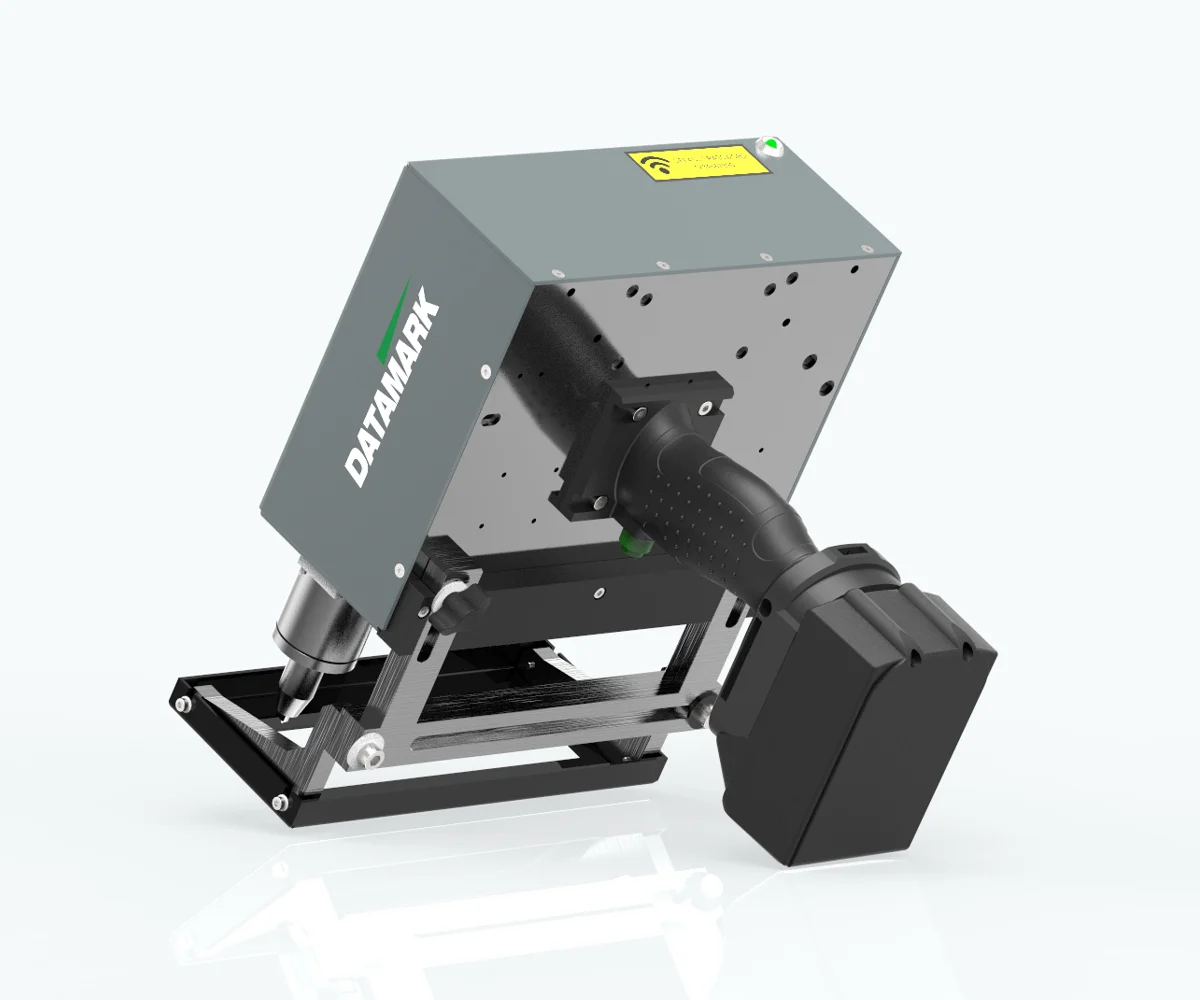

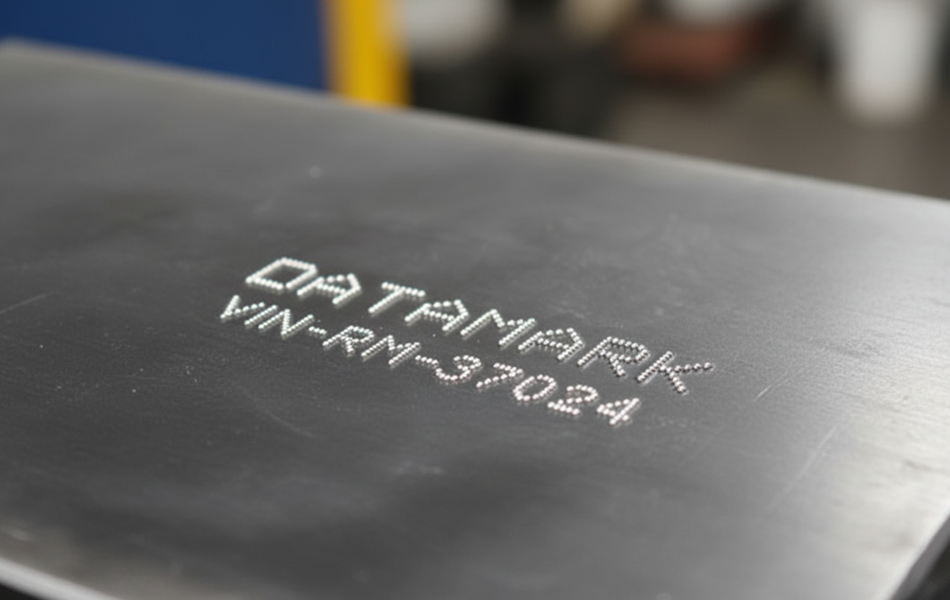

Identification is achieved in dot peen marking, also known as micro-percussion, through a pneumatically or electromagnetically driven stylus that strikes the surface. As a result, a series of small dots forms characters, codes, or logos. Through this process, the material is physically deformed, leading to a durable and low-maintenance permanent mark.

Advantages of Dot Peen Marking:

- High durability: Resistant to wear, heat, and solvents.

- Cost-effective: Requires minimal maintenance and offers a lower initial investment.

- Great for rough surfaces: Capable of marking castings, forged parts, and uneven surfaces easily.

How Laser Marking Works

Laser marking operates by directing a focused laser beam to alter the material’s surface using heat. Depending on the laser type, this method can engrave, etch, anneal, or change the material's colour without physical contact. Consequently, high-precision and clean results are achieved, even on complex designs.

Advantages of Laser Marking:

- High precision: Ideal for small, complex, or high-resolution designs.

- Non-contact process: Ensures tooling remains intact and marking stays clean.

- Marking speed: Perfect for high-volume production lines.

Datamark Product Range

At Datamark UK, industrial-grade marking systems are available for both technologies. In particular, our offerings include:

- Laser Marking Systems: Fibre, UV, and CO2 laser machines available in desktop, enclosed, and integrable versions.

- Dot Peen Marking Systems: Portable, benchtop, and integration-ready machines with air-powered or electromagnetic heads.

Applications

While dot peen marking is preferred in industries where durability is essential—such as metalworking, automotive, and heavy equipment—laser marking, in contrast, is widely used in electronics, medical devices, aerospace, and plastic components. Moreover, the choice of technology depends on both the material and specific production requirements.

Technology Comparison Table

| Feature | Dot Peen Marking | Laser Marking |

|---|---|---|

| Marking Method | Mechanical impact | Laser beam |

| Material Contact | Yes | No |

| Surface Suitability | Rough, curved, or coated surfaces | Smooth, flat surfaces preferred |

| Marking Depth | Adjustable (deep marking possible) | Typically shallow (except deep engraving) |

| Maintenance | Low | Very low |

| Typical Applications | Steel parts, tools, nameplates | Plastics, anodised metals, electronics |

| Initial Cost | Lower | Higher |

| Speed | Moderate | Very fast |

Conclusion

Whether you require deep, durable markings or high-speed, high-resolution laser engravings, Datamark UK offers the right solution. Therefore, explore our full range of industrial marking machines or contact us for expert advice and a personalised demo.